Assembly Line Balancing Problem & Solution Techniques

Assembly Line Balancing Problem (ALBP)

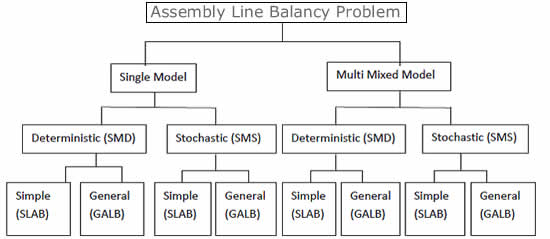

In this section, characteristics of balancing problems considered in the literature are provided and some classification schemes (Ghosh and Gagnon, 1989; Becker and Scholl,2006; Scholl and Becker, 2006) Ghosh and Gagnon (1989) classified the ALBP into four categories are given; as shown in Figure B

• Single Model Deterministic (SMD)

• Single Model Stochastic (SMS)

• Multi/Mixed Model Stochastic (MMS)

• Multi/Mixed Model Deterministic (MMD)

The SMD version of the ALB problem assumes dedicated, single model assembly lines where the task times are known deterministically and an efficiency criterion is to be optimized. This is the original and simplest form of the assembly line balancing problem (SALB). Introducing other restrictions or factors (e.g. parallel stations, etc) into the model and the problem becomes the General Assembly Line Balancing Problem (GALB)

Figure B. Classification of assembly line balancing literature (Ghosh and Gagnon 1989)

Figure B. Classification of assembly line balancing literature (Ghosh and Gagnon 1989)

The SMS problem category introduces the concept of task-time variability. This is more realistic for manual assembly lines, where workers’ operation times are seldom constant.

With the introduction of stochastic task times many other issues become relevant, such as station times exceeding the cycle time (and perhaps the production of defective or unfinished parts), pacing effects on workers’ operation times, station lengths, the size and location of inventory buffers, launch rates and allocation of line imbalances.

The MMD problem formulation assumes deterministic task times, but introduces the concept of an assembly line producing multiple products. Multi-model lines assemble two or more products separately in batches. In mixed-model lines single units of different models can be introduced in any order or mix to the line. Multi-mixed model lines introduce various issues that are not present in the single-model case. Model selection, model sequencing and launching rate(s) and model lot sizes become more critical issues here than in the single model case.

The MMS problem perspective differs from its MMD counterpart in that stochastic times are allowed. However, these issues become more complex for the MMS problem because factors such as learning effects, worker skill level, job-design and worker task time variability become more difficult to analyze because the line is frequently rebalanced for each model assembled.

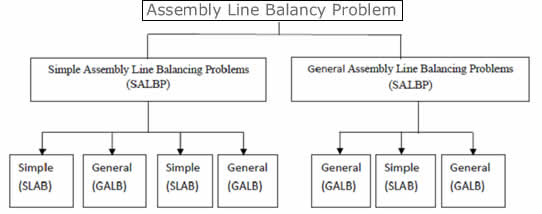

Scholl and Becker (2006) have classified the main characteristics of assembly line balancing problems considered in their several constraints and different objectives as shown in Figure:C. It has illustrated the classification of assembly line balancing problems.

Figure C: Classification of assembly line balancing problems (Scholl and Becker (2006)

Contact Consultants at VCS for all line balancing problem solutions

Keyword : Line Balancing, Line Balancing Problem, Line Balancing Problem solutions, Line Balancing Problem, assembly line balancing problems, line balancing techniques,line balancing solution

Download details article on Line balancing by Mr Nilesh Pendarkar of VCS consultants, from the attachment section of this articles